Expert Packaging Machine Repair Services to Improve Equipment Efficiency

Expert Packaging Machine Repair Services to Improve Equipment Efficiency

Blog Article

Exactly How to Make The Most Of Effectiveness With Expert Product Packaging Machine Repair Provider

In today's affordable landscape, the effectiveness of product packaging operations straight influences total performance and productivity. Comprehending the important function of packaging equipments, services need to acknowledge the signs that suggest a demand for repair service and the benefits of involving expert solutions. By focusing on professional repair services, organizations can not only minimize downtime however additionally improve the durability of their equipment. Selecting the ideal repair solution and executing effective preventative upkeep methods continues to be vital. Exploring these elements can disclose approaches that considerably elevate operational effectiveness, prompting a more detailed evaluation of ideal practices in this crucial area.

Understanding Product Packaging Maker Importance

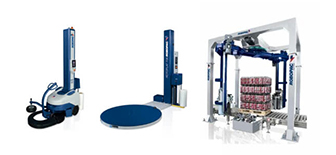

Packaging equipments play an indispensable role in boosting functional efficiency, product conservation, and customer appeal. High-speed product packaging devices can simplify production processes, lowering labor prices and reducing human mistake, while preserving high throughput prices.

In addition, advanced product packaging machines are made to fit numerous packaging kinds, such as boxes, bags, and bottles. This versatility permits producers to adjust to changing market demands and customer preferences without substantial downtime. Additionally, reliable packaging makes certain item honesty during transportation and storage space, minimizing waste and spoilage and ultimately adding to sustainability efforts.

In addition, product packaging equipments integrate perfectly with other manufacturing systems, promoting a smooth operations from manufacturing to distribution. This interconnectedness not only enhances performance however also offers important information analytics for continual improvement. In recap, the significance of packaging devices in contemporary manufacturing can not be overemphasized; they are vital for keeping affordable benefit and achieving operational excellence in today's hectic service atmosphere.

Signs Your Device Requirements Repair

Identifying the indications that your product packaging machine calls for repair work is vital for keeping manufacturing performance and reducing downtime. Regular monitoring of machine performance can help spot issues prior to they escalate into significant problems.

One of the initial signs is an uncommon increase in noise degrees during procedure. It may suggest mechanical wear or misalignment if the machine starts to generate grinding or clattering audios. Furthermore, inconsistent item outcome, such as uneven product packaging or mislabeling, can suggest that the equipment's calibration is off, requiring immediate interest.

Another essential indication is constant mistake messages or unanticipated shutdowns. These interruptions can seriously affect output and signal underlying electric or software application issues. If you observe a decrease in rate or performance, with the maker taking longer to complete jobs, it might be a forerunner to more extreme mechanical failings.

Last but not least, physical signs such as fraying belts, leaking fluids, or excessive resonance ought to not be ignored, as they usually point to components that get on the edge of failure - packaging machine repair. Immediately dealing with these symptoms can prevent costly repair work and make certain optimal functional performance

Advantages of Specialist Repair Services

Additionally, professional repair service services typically have accessibility to innovative diagnostic tools and technologies that facilitate a detailed evaluation of devices problem. This not just aids in prompt repair work yet additionally permits anticipating maintenance, avoiding future malfunctions and his response expanding the lifespan of machinery.

In addition, utilizing expert solutions can lead to improved safety criteria, as experienced specialists are fluent in sector guidelines and ideal methods. This lowers the danger of crashes triggered by incorrect handling or maintenance. Ultimately, the financial investment in expert repair work solutions equates to cost savings by maximizing machine performance, boosting item quality, and making certain compliance with safety standards, every one of which add to a much more effective production atmosphere.

Choosing the Right Repair Work Solution

A repair service that uses 24/7 support can stop minor problems from rising right into costly manufacturing stops. Look for companies that supply a detailed solution arrangement, outlining their warranties, pricing frameworks, and parts accessibility.

In addition, inspect consumer evaluations and testimonies to determine the reliability and professionalism and trust of the service copyright. A respectable business will certainly have a history of satisfied clients, which speaks quantities regarding their service quality. Last but not least, guarantee that the specialists are licensed and educated in the most up to date innovations and ideal practices, as this experience is necessary for effective repair services and maintenance. By meticulously picking a fixing service, you can improve the long next page life and efficiency of your product packaging devices.

Preventative Maintenance Methods

Applying preventative maintenance strategies is crucial for ensuring the ideal performance and longevity of packaging devices. Regularly scheduled upkeep not only reduces the chance of unforeseen breakdowns yet also boosts total operational effectiveness.

A proactive maintenance routine need to include routine assessments, lubrication of relocating components, and checking for damage on crucial parts. These evaluations can identify prospective issues before they rise right into pricey repair work or downtime. Furthermore, keeping precise documents of upkeep activities can aid track machine performance trends and guide future maintenance choices.

Educating employees on correct operating procedures is another vital facet. Workers should be enlightened on acknowledging very early indicators of equipment breakdown, which can facilitate prompt treatment. Furthermore, utilizing resonance analysis and thermal imaging innovation can better enhance the maintenance method by pinpointing issues that might not show up to the naked eye.

Conclusion

In final thought, maximizing effectiveness with skilled product packaging device repair solutions demands a positive technique that consists of regular maintenance, timely fixings, and the proficiency of skilled specialists. Executing advanced analysis tools and fostering connections with reputable repair service solutions add to boosted operational efficiency and reduced downtime. By focusing on these methods, services can ensure the durability and efficiency of their packaging equipment, ultimately bring about enhanced performance and adaptability in response to progressing production needs.

Understanding the vital function of product packaging devices, services must acknowledge the click here for more info signs that indicate a requirement for repair work and the benefits of engaging expert services.Attending to the signs of wear and malfunction in packaging makers promptly is only component of the formula; leveraging professional repair work services can significantly improve functional efficiency.Selecting the appropriate product packaging machine repair service is important for preserving operational effectiveness and lessening downtime. By meticulously picking a repair service, you can enhance the durability and performance of your packaging devices.

In final thought, maximizing performance with expert product packaging device repair work solutions requires a positive technique that consists of normal upkeep, timely repairs, and the competence of competent technicians.

Report this page